Getting Started with HGG Machines

PypeServer for HGG Machines

This document covers topics specific to HGG machine working well with PypeServer. Topics include:

General network layout for using PypeServer with the machine

HGG ProCAM settings and PypeServer settings for creating program cut files from PypeServer

Cut-file monitoring for PypeServer part cut status

Using the Last Cut in Chuck feature--where the end of the pipe is used as the end of the last nested part.

Contents

2 General overview of network layout 2

3.1 HGG Machine ProCAM settings 3

4.1 Writing NC files to a file-share for use in ProCAM 4

4.2 Loading and Cutting a PypeServer Cut Program 5

4.2.1 Automated Loading of PypeServer Cut Programs into ProCAM 5

4.2.2 Manual Loading of PypeServer Cut Programs into ProCAM 6

4.3.1 Cutting Dead Zone = <distance> 7

4.3.2 Last Cut in Chuck Settings 7

4.4 Cut-File and PypeServer Part Status Synchronization 8

4.4.1 HGG part status monitoring 9

4.4.2 NC File Timer Interval 10

4.4.4 Is Metric = <checkbox> 11

4.4.5 StaggerStraightCutStartRotationDist = <distance> 12

Terms

Cut Program: A file created by PypeServer to be run by the HGG ProCAM software. These files are in JSON format, and as such have the .json suffix.

NC files or NC program: A generic acronym for the generic name Numerical Control, which traditionally means "GCode". In this case the "GCode" format is JSON, and thus any reference to NC file is the same as a Cut Program.

JSON: "JavaScript Object Notation. A common format used for passing information from one software program to another. If you open a Cut Program, the format will be in JSON. Some viewers make reading these easier. NotePad++ has a nice JSON viewer, and browsers will often format them for easy reading.

General overview of network layout

PypeServer can be run from any Windows computer on a network. Users from different disciplines use PypeServer for different parts of the fabrication workflow. If PypeServer is being used by different disciplines, then the PypeServer machine (which has the SQL server) needs to be on the company domain such that CAD programmers, Detailers, Shop Foremen and others can run PypeServer.

The basic configuration looks like this:

Internet connectivity allows PypeServer to assist in initial system configuration and ongoing support.

PypeServer can work with your IT department to get PypeServer joined to the domain. For more IT-level information, see the PypeServer training document "Getting Started with PypeServer", section 2.

Creating Cut Programs

PypeServer outputs HGG readable cut programs to JSON files that define the pipe, parts on the pipe, and cuts on the parts.

HGG Machine ProCAM settings

On the HGG machine you can run PypeServer cut programs with either HGG's ProCAM, or PypeServer calculating torch compensations and leadins and leadouts. You choose which program will do the calculations in this window in ProCAM:

Pros and Cons of each:

Using ProCAM:

Pro: They've been doing this for decades--with their own machines.

Cons:

The torch paths (offsets, beam divergence, leadins and outs, and tabs) you see in PypeServer are not what will be cut through ProCAM.

Some features such as Last Cut in Chuck are not supported because it is not possible to know where to position the torch on the start of the program because the actual lead-in start location/distance is not known.

Using PypeServer

Pros:

What you see in PypeServer is what you get

Features including Last Cut In Chuck and Tabs are supported

Cons:

PypeServer compensation instructions may not always work optimally with the HGG machine. (Testing is not as extensive as HGG's own ProCAM system.)

PypeServer settings

The following dialog highlights settings that users may want to change. To get to these settings, open Settings??Machine Settings to see this dialog. You will need to enter the Admin password to see all the fields.

Writing NC files to a file-share for use in ProCAM

The Folder or IP Address is where the NC files will be written to.

This is where PypeServer writes the .json files.

PypeServer needs read/write access to this location so that it can manage files and cut status based on the files. More on that in section Cut-File and PypeServer Part Status Synchronization.

The folder should be visible to all instances of (computers running) PypeServer. This can be done by creating a domain level mapping, such as , or by creating a mapped address such as Z:\\CutPrograms where the mapped address is the same for all computers running PypeServer.

This folder should be easily accessible to the HGG ProCAM program so that users at the machine can easily load these files to the machine. Ideally this location maps to a folder on the HGG computer so that the .json files are always available at the machine, even if there are network problems or other computers are off. If ProCAM has a default folder for remote cut-files, it would be best to share this and allow PypeServer to write directly to that folder.

The Data Transfer Mode instructs the system to write NC files to this folder

The NC file Tag is .json and should not be changed

Loading and Cutting a PypeServer Cut Program

The "Create NC File" button is on the Parts, Nesting or Pipes tab.

By clicking on this button users can create *.json files that can be loaded by ProCAM for cutting. These can be loaded manually from within the ProCAM application, or can be loaded automatically from PypeServer.

Automated loading workflow:

User loads a part or pipe nesting from PypeServer to the machine. This can be done ONLY at the machine where procam.exe is located.

PypeServer automatically starts an instance procam.exe, which will automatically load the part or nesting into the HGG UPC (app that actually runs the machine).

The user can run the part or pipe nesting immediately after loading.

Manual loading workflow (the more common workflow):

User loads a part or pipe nesting from PypeServer to the machine. This can be done at any computer that has access to the file-share where the NC files are written.

The NC files are not automatically loaded into the HGG UPC, so more than one file can be staged for cutting.

Machine users then use ProCAM to open the files for cutting.

Automated Loading of PypeServer Cut Programs into ProCAM

"Automated Loading" means that when a user, at the HGG machine, creates an NC cut file (*.json file written to the shared folder discussed above), then it will automatically appear in the HGG machine as the cut program loaded, ready to be cut.

This automation can run only on computers with ProCAM installed.

Open Settings??Machine Settings to see this dialog. You will need to enter the Admin password if that is required.

The Computer Running Procam field specifies the HGG machine computer name. If this is blank, automatic loading will not be performed.

The Procam Exe Location is the path to procam.exe as seen by the Computer Running Procam.

To NOT run automatic loading, just leave the Computer Running Procam blank.

Manual Loading of PypeServer Cut Programs into ProCAM

Please contact HGG support for how to manually load cut programs into ProCAM into the machine from within the ProCAM application. Users typically just click an Open program on the ProCAM menu and open the <filename>.json file created by PypeServer.

General positioning

Cutting Dead Zone = <distance>

This is the area that the torch should not go because it my hit the chuck. (Note that if you add an extension to your pipe, you can specify this for the pipe and PypeServer with then nest in this area.

Last Cut in Chuck Settings

The Last Cut in Chuck feature allows you to use the chucked end of the pipe as the last cut on the last part in the nesting. This saves you time cutting, and allows PypeServer to nest through the nesting Dead-Zone. See also the "Last Cut In Chuck" training document.

Requirements:

You must use PypeServer's cut compensations and leadin/leadout. See HGG Machine ProCAM settings.

You should not have any cuts in the dead-zone.

Please refer to this diagram for the settings in this section.

MachineCanMoveToPositionOnStart = <True/False>

This parameter is also specific for the Last Cut in Chuck feature. It indicates if the machine supports moving to a position relative to its Machine Zero position.

MachineCanMoveToPositionOnStart = True

If this is supported, set this to true, as it will eliminate the need to measure the distance from the end of the pipe to the start.

Requirements when True:

The pipe must be chucked at exactly the distance from machine zero each time you use this feature, so be sure to have a marking or index stop for this placement.

MachineCanMoveToPositionOnStart = False

If this feature is not supported by the HGG machine, then set this to false. When set to false, you will be required to move the torch centerline (when straight up) a specified distance from the chucked end of the pipe before starting the program.

Machine Zero to End of Pipe = <distance>

This applies only to Last Cut in Chuck feature and is only used if MachineCanMoveToPositionOnSart = True.

This is the distance from the machine zero position to where the pipe ends in the chuck (distance A in the diagram above). This number should be positive or negative to match machine direction from zero. Referring to the diagram above, the chuck is "behind" machine zero, (machine moves positive to the right) and so the number is negative. Users typically do not change this value once they've determined the chuck stop location, measured, and set this value. Be sure to mark or index where your pipes will stop in the chuck.

Cut-File and PypeServer Part Status Synchronization

PypeServer can monitor files sent out to the machine to maintain the status of scheduled parts. Scheduled Part status can be:

Not Nested

Nested

On Machine

Cut

Scrapped

For more information on the standard PypeServer-supported method of monitoring NC files to maintain part status, please see the training video on "NC File Management". To turn this monitoring on, set these fields:

Data Reporting Mode = "SystemWatchesFiles" causes the application at the computer named in Computer Watching Files to monitor for changes.

The Computer Watching Files can be any computer that can see the Folder or IP Address

Note that this monitoring can (and typically should) be run concurrent with the HGG custom monitoring discussed below.

HGG part status monitoring

For a background understanding of file monitoring, please see the training video on "NC File Management"

When configured, ProCAM will automatically write file status updates to a folder under the Folder or IP Address. PypeServer can be configured to monitor for these changes, such that when a part or nesting is cut, ProCAM will report it and PypeServer will update parts to cut as they are cut. This runs independent of any loading automation, and can be run from any computer that has access to the Folder or IP Address location. To enable this, set these two fields:

The Computer Monitoring Hgg Reporting is the computer that will check for updates by ProCAM. Typically this is the main PypeServer computer, so long as that computer can see the Folder or IP Address Location.

NC File Timer Interval

With either the standard monitoring or HGG custom monitoring, the time period to check (in seconds) is set with the NC File Sync Timer Seconds. Typically this is set to 60 seconds.

LeadIn/Out Settings

These settings (highlighted in Green) are seldom changed. These are only limits. The actual leadin settings are made in the Torch settings, but they must fall within these limits.

For more information, please see the document "Torch End of Cut Leadout and Tuning" in the PypeServer training system.

Leadin Min Distance = <distance>

This is the minimum distance allowed for a leadin in PypeServer. A good performing machine can have a short leadin.

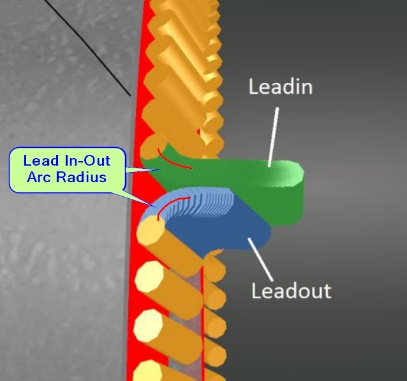

Lead In-Out Arc Radius = <distance>

Lead In-Out Arc Radius = <distance>

This is the radius of the turn made by the leadin. Note that this is not the overall length of the leadin. Having this as a small radius decreases the range of gouging, but the tradeoff is that if it's too tight, the machine may fault or have difficulty making turn smoothly.

Leadin Steps = <integer number>

This is the number of steps PypeServer creates for the leadin. This adjustment is not typically made by the user.

Is Metric = <checkbox>

If you set this to Metric, all your machine and torch settings will be interpreted as metric. You can still have standard (Imperial) measurements parts. Note that you do not need to set this to Metric just because your machine runs in metric. This is only a convenience to allow users to work in familiar units.

StaggerStraightCutStartRotationDist = <distance>

When straight cuts are nested together without any rotation between starts and finish, the leadins and leadouts can overlap and cause the torch to burn incorrectly or fault because it hits the leadin/out gap of the previous cut. This instructs PypeServer nesting to rotate the next leadin by a distance (around the pipe) so as to avoid this intersection. Shown below is a 4.5" pipe with StaggerStraightCutStartRotationDist = 1 inch.

Related Articles

FAQ: Getting Started

FAQ: Getting Started With PypeServer Enterprise Startup Q: Can we do training before the machine is fully setup? A: Yes, however it is best done when the machine is installed and ready to use so that you can use what you’ve learned. Also, it is ...Getting Started with PypeServer

Getting Started with PypeServer (and Frequently Asked Questions) This document covers what to do in preparation for using the PypeServer software, and maintaining the PypeServer system. Contents 1 User Information 3 1.1 Overview 3 1.2 General Layout ...Getting Started with PypeServer

1 User Information 1.1 Overview · The PypeServer Kiosk is an industrially enclosed computer system that sits next to the pipe cutting machine. · PypeServer is currently (as of 2020) running Windows 10 Professional. It can also be run on Window 7 ...Pypeserver with EdgeConnect Machines

Pypeserver with EdgeConnect Machines PypeServer with EdgeConnect machines Machine configuration When configuring your machine, some preparatory steps are required in order to get meaningful test results. Getting axial directions correct This is done ...Getting Started with label Printing

Getting Started with label Printing Getting Started with Label Printing in PypeServer This document explains what PypeServer provides for Label Printing, what the customer must procure and do to set up NiceLabel and label printing, and links to ...